Analisis Dimensional Reaktor Berpengaduk Statis untuk Produksi Biodiesel

Abstract

Abstract

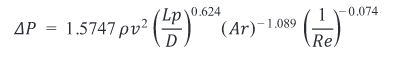

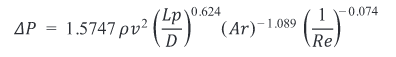

Biodiesel production can be done using static mixing reactor (SMR). The production by this method requires less energy than blade agitator. However, the use of elements in the helix-shaped stirrer reactors causing large pressure drop. The other factors that affect the flow in the SMR can be determined using dimensional analysis. Dimensional analysis can be used to eliminate the variables that are not required so that can be done to optimize the energy used in the SMR design. The variables that influence the pressure drop (ΔP) in the SMR can be formulated into mathematical equation as:

Total irreversibility due to the use of a static mixer in the SMR tested is 0.237 W.

Abstrak

Produksi biodiesel dapat dilakukan dengan menggunakan reaktor berpengaduk statis atau SMR (Static Mixing Reactor). Pembuatan biodiesel dengan metode ini membutuhkan energi yang lebih kecil dibandingkan dengan menggunakan blade agitator. Namun demikian penggunaan elemen pengaduk yang berbentuk helix dalam reaktor menimbulkan pressure drop yang besar. Faktor-faktor lain yang berpengaruh terhadap aliran di dalam SMR dapat ditentukan dengan menggunakan analisis dimensional. Analisis dimensional mampu menghilangkan variabel-variabel yang tidak diperlukan sehingga dapat dilakukan untuk mengoptimalkan energi yang digunakan dalam perancangan SMR. Variabel-variabel yang berpengaruh terhadap pressure drop (ΔP) di dalam SMR yang dapat diformulasikan ke dalam bentuk persamaan matematis sebagai:

Ketakmampubalikan total akibat penggunaan elemen berpengaduk statis yang diuji adalah 0,237 W.

References

Bakker, A., R.D. Laroche, E.M. Marshall. 2000. Laminar flow in static mixers with helical elements. The Online CFM Book [Internet]. [diunduh 2013 Nov 28]. Tersedia pada: http://www.bakker.org/cfm.

Bridgman, P.W. 1922. Dymensional Analysis.Yale (US): Yale Univ Pr.

Darnoko, D., M. Cheryan. 2000. Kinetics of palm oil transesterification in a batch reactor. JAOCS. 77(12):1263-1267.

Freedman, B., W.F. Kwolek, E.H. Pryde. 1986. Quantitation in the analysis of transesterified soybean oil by capillary gas chromatography.

JAOCS. 63:1370-1375.

Knothe, G., J.V. Gerpen, J. Krahl. 2005. The Biodiesel Handbook. Champaign, Illinois (US). AOCS Pr.

Moser, B.R. 2009. Biodiesel production, properties, and feedstocks. In Vitro Cellular & Developmental Biology – Plant. 45:229-266.

Panggabean, S. 2011. Analisis kinetika reaksi transesterifikasi pada produksi biodiesel secara katalitik dengan static mixing reactor [tesis]. Bogor (ID): Institut Pertanian Bogor.

Song, H.S., S.P. Han. 2005. A general correlation for pressure drop in a Kenics static mixer. Chem Eng Science. 60:5696-5704. doi:10.1016/j.

ces.2005.04.084.

Soolany, C., A.H. Tambunan, R. Sudrajat. 2015. Kajian penggunaan statick mixing reactor pada proses produksi biodiesel secara katalitik

dengan sistem continue. J Penelitian Hasil Hutan. 33(3):261-272.

Thakur, R.K., Ch. Vial, K.D.P. Nigam, E.B. Nauman, G. Djelveh. 2003. Static mixers in the process industries - a review. IChemE. 81:787-826.

Vicente, G., M. Martınez, J. Araci. 2004. Integrated biodiesel production: a comparison of different homogeneous catalysts systems. Bioresource

Technology. 92:297–305.

Authors

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors submitting manuscripts should understand and agree that copyright of manuscripts of the article shall be assigned/transferred to Jurnal Keteknikan Pertanian. This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License (CC BY-SA) where Authors and Readers can copy and redistribute the material in any medium or format, as well as remix, transform, and build upon the material for any purpose, but they must give appropriate credit (cite to the article or content), provide a link to the license, and indicate if changes were made. If you remix, transform, or build upon the material, you must distribute your contributions under the same license as the original.