Optimasi Proses Ekstrusi Texturized Vegetable Protein di PT XYZ

Abstract

Texturized vegetable protein (TVP) is one of the meat analogue products made by modifying the structure of vegetable protein come to be meat-like texture. Several advantages could be obtained by consuming meat analogue. It could reduce the risk of disease and could be consumed by someone who could not consume meat, either because of health problems or beliefs meat consumption will increase continually inline with increasing population, economic level, and public awareness to nutrition. The TVP using was increased as a protein source alternative. The TVP demand of PT. XYZ increase continued to, but the number of production machines was limited. The companies need to optimize their available machines to meet their demand. This research aimed to optimize the production capacity of TVP. Defatted soy flour was used as the source of protein. Several parameter used in this research were flour flow capacity, water flow capacity, screw rotation speed, and extruder temperature. The response parameters used were water absorption, water content, color, bulk density, and grain shape. The data was collected by 21 runs that is repeated twice for each run. The optimization process was carried out using Design Expert 10 (DX-10) through Response Surface Method (RSM). The optimum of process conditions combination of the TVP extrusion were: flour flow capacity 225kg/hour; water flow capacity 35.54 Hz; extruder temperature 130.70°C; and the screw rotation speed 375.18 rpm. The verification result showed that the value of each response was within the Confident Interval (CI) range.

Downloads

References

Chakraborty SK, Singh DS, Kumbhar BK. 2014. Influence of extrusion conditions on the colour of millet-legume extrudates using digital imagery. Irish J Agriculture Food Res 53(1): 65-74.

Cheng H, Hansen JH. 2015. Extrudate expansion model in a twin-screw extrusion cooking process considering melt rheological property. Food Bioprocess Technol 9: 604-611. DOI: 10.1007/s11947-015-1655-0.

Day L, Swanson BG. 2013. Functionality of protein-fortified extrudates. Compr Rev Food Sci F 12: 546-564. DOI: 10.1111/1541-4337.12023.

González RJ, Cavada EP, Pena JV, Torres RL, Greef DMD, Drago SR. 2013. Extrusion conditions and amylose content affect physicochemical properties of extrudates obtained from brown rice grains. Int J Food Sci 2013: 1-8. DOI: 10.1155/2013/584148.

Hair J, Kuppelwieser V, Sarstedt M. 2014. Partial least squares structural equation modeling (PLS-SEM): An emerging tool for business research. Eur Bus Rev 26(2): 106-121. DOI: 10.1108/EBR-10-2013-0128.

Hidayat BT, Wea A, Andriati N. 2018. Physicochemical, sensory attributes and protein profile by SDS-PAGE of beef sausage substituted with texturized vegetable protein. Food Res 2(1): 20-31. DOI: 10.26656/fr.2017.2(1).106.

Isik E. 2007. Some engineering properties of soybean grains. Am J Food Technol 2(3): 115-125. DOI: 10.3923/ajft.2007.115.125.

Kusuma HAW, Kumalaningsih S, Pranowo D. 2019. Optimasi suhu dan konsentrasi maltodekstrin pada proses pembuatan serbuk lobak dengan metode foam mat drying. J Teknol Manajemen Agroind 8(3): 171-182. DOI: 10.21776/ub.industria.2019.008.03.2.

Kusumaningrum A, Gunam IBW, Wijaya IMM. 2019. Optimasi suhu dan pH terhadap aktivitas enzim endoglukanase menggunakan response surface methodology (RSM). J Rekayasa Manajemen Agroind 7(2): 243-253. DOI: 10.24843/JRMA.2019.v07.i02.p08.

Muhandri T, Subarna, Mustakim I. 2013. Optimasi proses pembuatan mi sorgum dengan menggunakan ekstruder ulir ganda. J Sains Terapan 3(1): 1-7. DOI: 10.29244/jstsv.3.1.1-7.

Nugroho MF, Murtini ES. 2017. Inovasi peningkatan kandungan gizi jajanan tradisional klepon dengan modifikasi bahan dan warna. J Pangan Agroind 5(1): 92-103.

Nurmiah S, Syarief R, Peranginangin R, Nurtama B. 2013. Aplikasi response surface methodology pada optimalisasi kondisi proses pengolahan alkali treated cottonii (ATC). J Pascapanen Bioteknol Kelautan Perikanan 8(1): 9-22. DOI: 10.15578/jpbkp.v8i1.49

Osen RJ. 2017. Texturization of Pea Protein Isolates Using High Moisture Extrusion Cooking [Disertasi]. München (DE): Technischen Universität München.

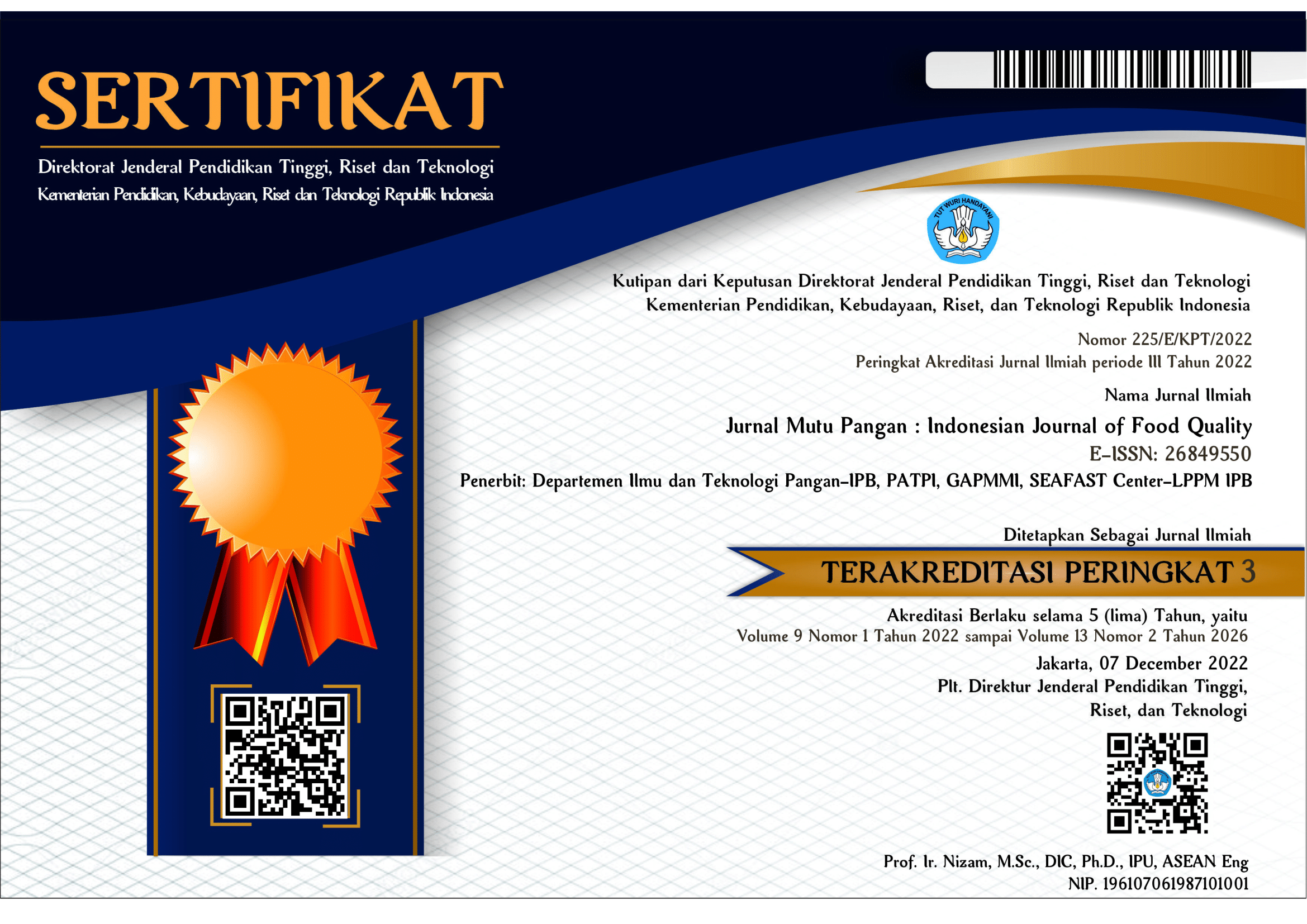

Prabudi M, Nurtama B, Purnomo EH. 2018. Aplikasi response surface methodology (rsm) dengan historical data pada optimasi proses produksi burger. J Mutu Pangan 5(2): 109-115.

Priyanto R, Fuah AM, Aditia EL, Baihaqi M, Ismail M. 2015. Peningkatan produksi dan kualitas daging sapi lokal melalui penggemukan berbasis serealia pada taraf energi yang berbeda. J Ilmu Pertanian Indo-nesia 20(2): 108-114. DOI: 10.18343/jipi.20.2.108.

Ratnaningsih, Vidiantika D, Sukasih E, Setyadjit. 2018. Penggunaan response surface methodology pada optimasi proses pengolahan bawang merah iris in brine. J Penelitian Pascapanen Pertanian 15(1): 12-24. DOI: 10.21082/jpasca.v15n1.2018.12-24.

Samard S, Gu BY, Ryu GH. 2019. Effects of extrusion types, screw speed and addition of wheat gluten on physicochemical characteristics and cooking stability of meat analogues. J Sci Food Agri 99(11): 4922-2931. DOI: 10.1002/jsfa.9722.

Sarawong C, Schoenlechner R, Sekiguchi K, Berghofer E, Perry KW. 2014. Effect of extrusion cooking on Physicochemical properties, resistant starch, phenolic content and antioxidant capacities of green banana flour. Food Chem 143(2014): 33-39. DOI: 10.1016/j.foodchem.2013.07.081.

Sibarani M, Allan MP, Santika PM. 2018. Perancangan unit extruder pada mesin extrusion lamination flexible packaging. J Teknik Mesin-ITI 2(2): 42-45. DOI: 10.31543/jtm.v2i2.155.

Singh SK, Muthukumarappan K. 2014. Single screw extrusion processing of soy white flakes based catla feed. J Food Res 4(1): 1-9. DOI: 10.5539/jfr.v4n1p1.

Sobowale SS, Bamgbose S, Adeboye AS. 2016. Effect of extrusion variables on the extrudate properties of wheat plantain noodle. J Food Process Technol 7(2): 547. DOI: 10.4172/2157-7110.1000547.

Syahrul, Syarif R, Hermanianto J, Nurtama B. 2017. Optimasi proses penggorengan tumpi-tumpi dari ikan bandeng menggunakan response surface methodology. J Pengolahan Hasil Perikanan Indonesia 20(3): 432-445. DOI: 10.17844/jphpi.v20i3.19762.

Ulfa R, Hariyadi P, Muhandri T. 2014. Rendemen giling dan mutu beras pada beberapa unit penggiling padi kecil keliling di Kabupaten Banyuwangi. J Mutu Pangan 1(1): 26-32.

Wang S, Kowalski RJ, Kang Y, Kiszonas AM, Zhu MJ. 2017. Impacts of the particle sizes and levels of inclusions of cherry pomace on the physical and structural properties of direct expanded corn starch. Food Bioprocess Technol 10: 394-406. DOI: 10.1007/s11947-016-1824-9.

Ye J, Hu X, Luo S, Liu W, Chen J, Zheng Z, Liu C. 2017. Properties of starch after extrusion: A Review. Starch 70(11-12): 1700110. DOI: 10.1002/star.201700110.